FIELD-TESTED

HIGHCAMP3 Dyneema®

16.000,00 DKK

The lightweight advanced base camp tent

The HIGHCAMP3 Dyneema® is an advanced base camp tent designed to accommodate three users and their gear, weighing in at just 3.4 kg. Its geodesic structure, combined with materials such as Dyneema® and Nanovent® waterproof-breathable membrane, makes it a robust yet lightweight solution for demanding conditions.

TECHNOLOGIES

Biosourced Dyneema

TENT WALLS

3-LAYER NANOVENT + CORDURA

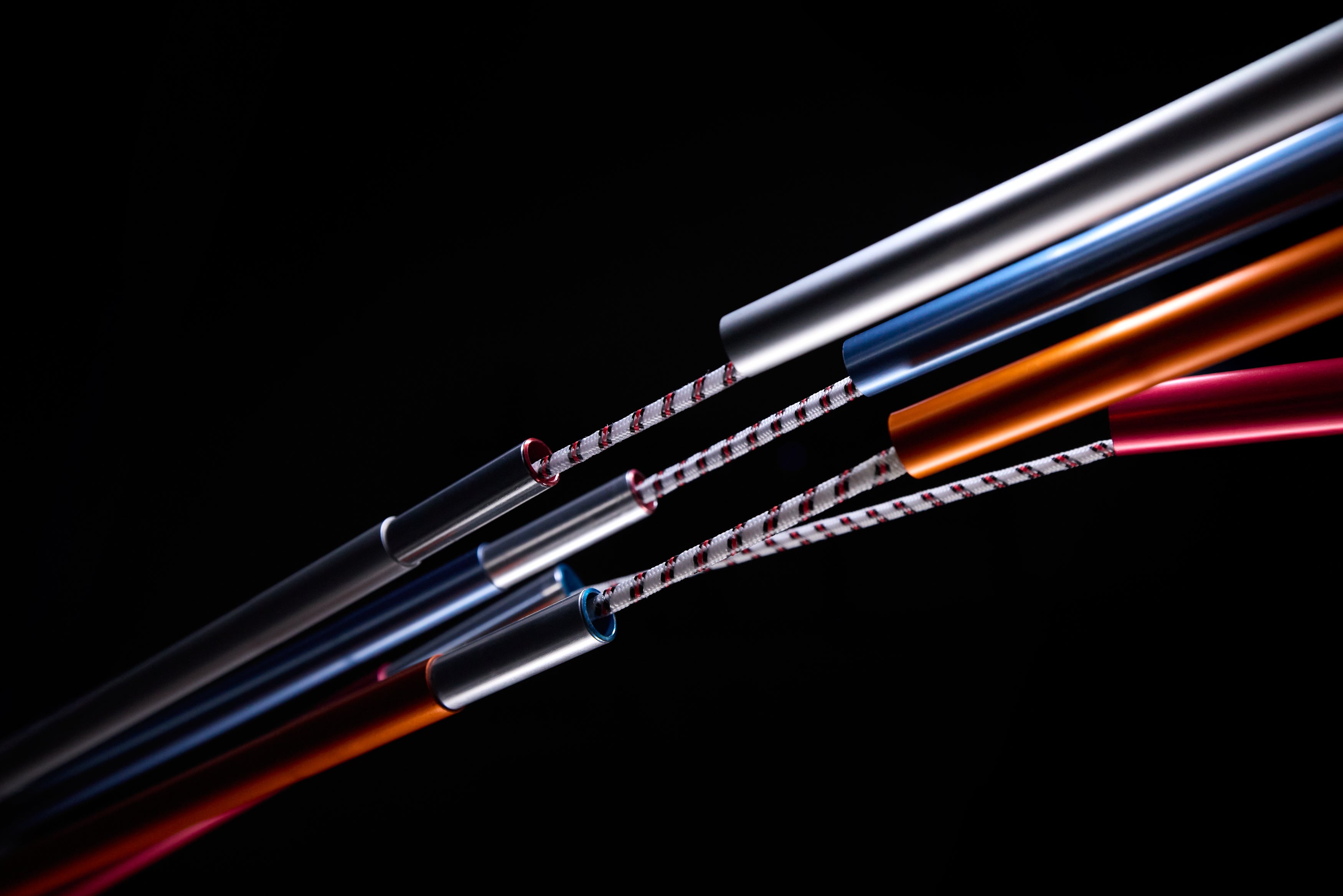

POLES

DAC

TENT FLOOR

Dyneema Composite Fabric (DCF)